The Biorecycling Machine project by Matt Harkness proposes human body as recycling infrastructure

Polylactic acid (PLA) is a versatile commercial biodegradable bioplastic that is typically produced from 100% renewable resources such as corn starch or other fermented biomass. To mitigate the issue of global plastic waste, polylactide is on the rise and projected to replace a significant portion of conventional petroleum-based plastics, over the next decade. However, presently, there is a lack of proposal for recycling and disposal of these new materials. The Biorecycling Machine project by Matt Harkness combines the science of PLA medical implants to present a potential for bioplastic recycling. PLA

This project is a response to this situation where, Critical Making and Speculative Design are used to interrogate the petrochemical industry’s 'Reduce, Reuse, Recycle' campaign, introduced in the 1970s. Central to this is placing the responsibility of recycling plastic to the consumers through increasing affordability of 3D printing.

Polylactic acid is an extensively used polymer in medical applications such as drug delivery systems and PLA biomedical implants can safely reside inside human tissue for extended periods of time while being slowly absorbed and eventually excreted by the body.

Matt Harkness explains, “I came across this idea while conducting research for my PhD around disposal methods for petroleum-based plastics as well as new bioplastics while thinking about alternative methods to reuse or dispose of these materials. Building on this, I considered how a device like the Biorecycling Machine is not entirely unreasonable as microplastics are incredibly pervasive.”

He continues, “For example, microplastics can already be found inside fifty percent of humans on Earth and have recently been discovered in the placenta. Moving from this, I linked the biocompatibility of polylactic acid with the network of the human body as recycling infrastructure.”

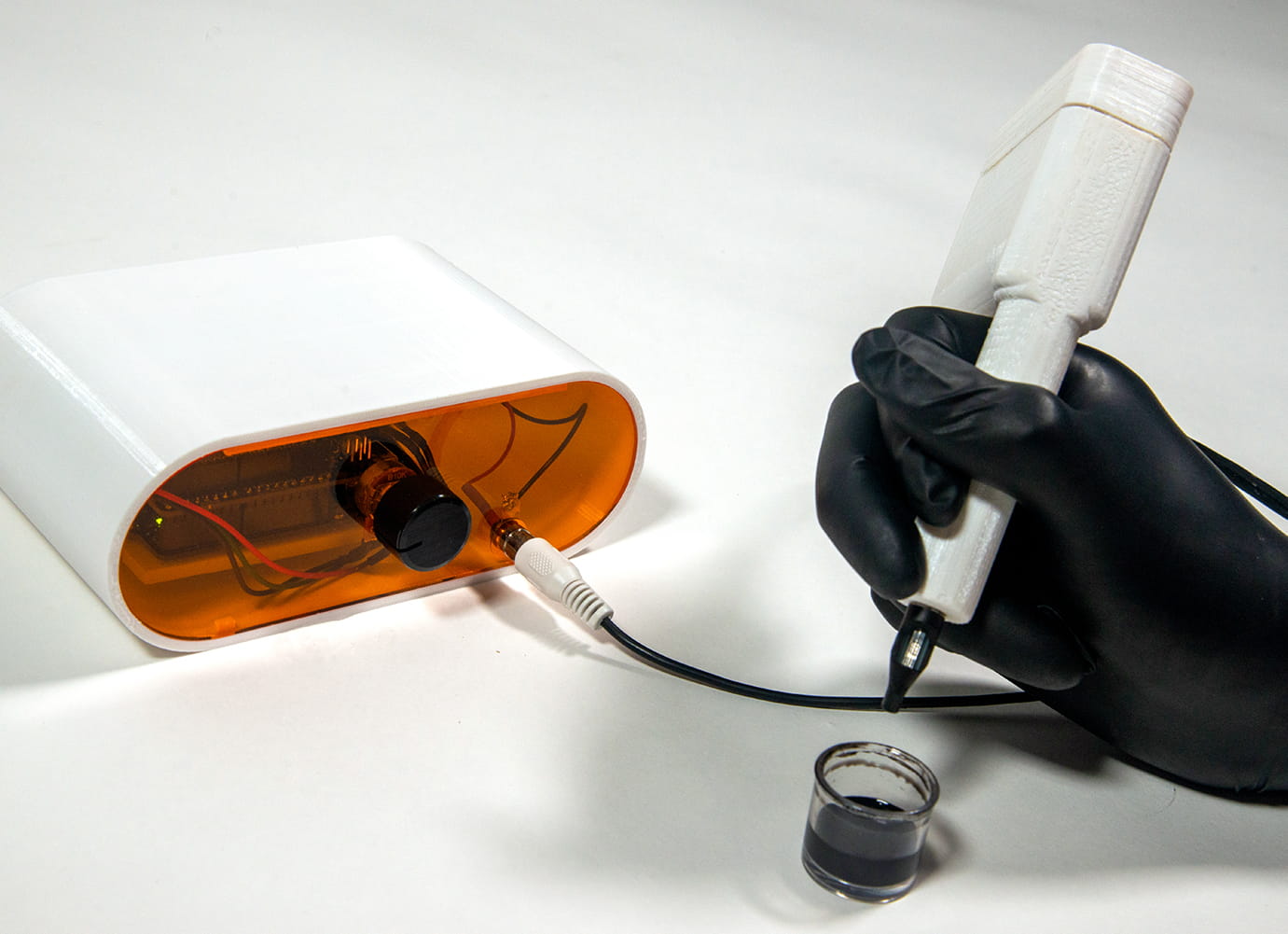

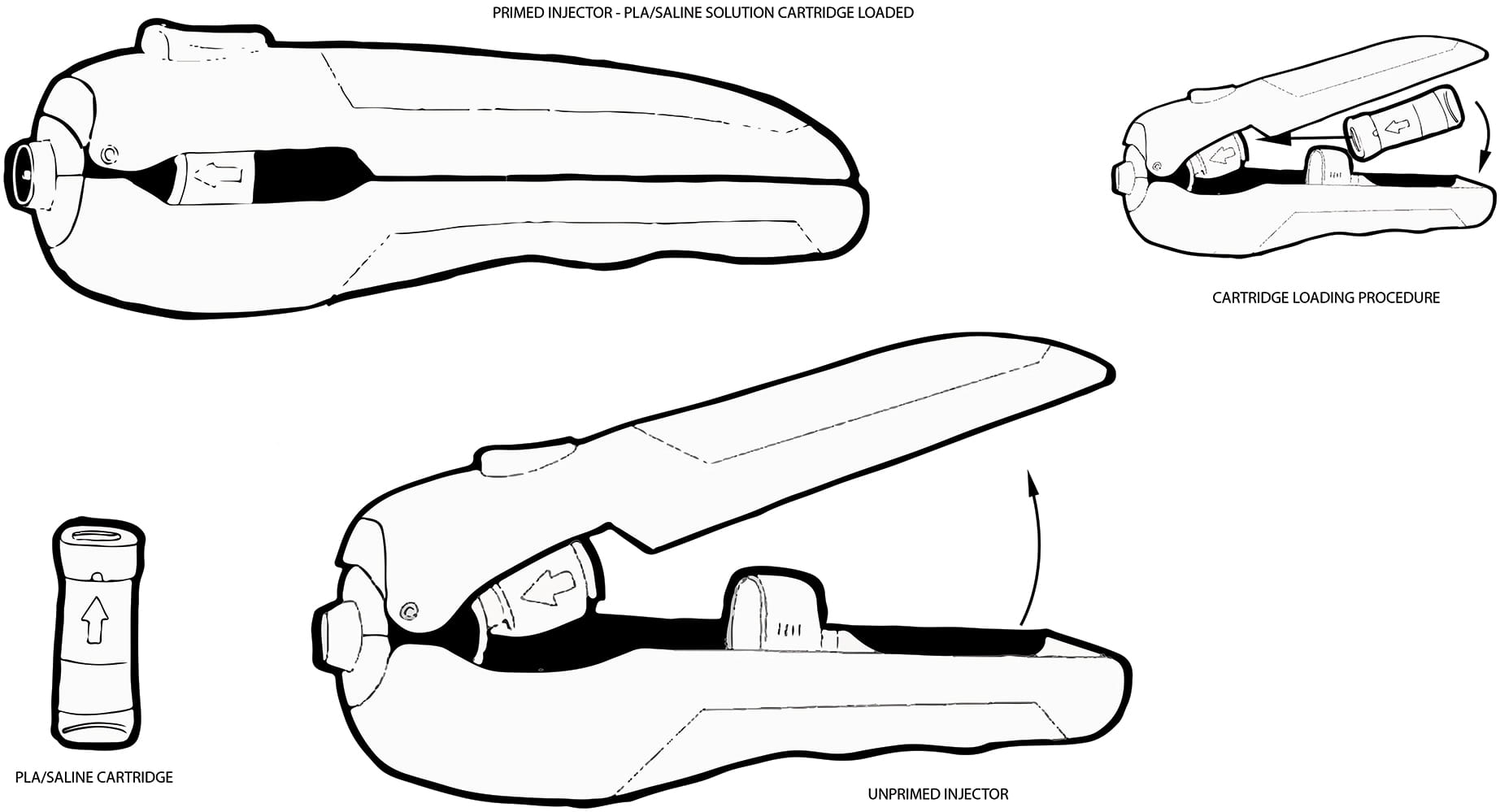

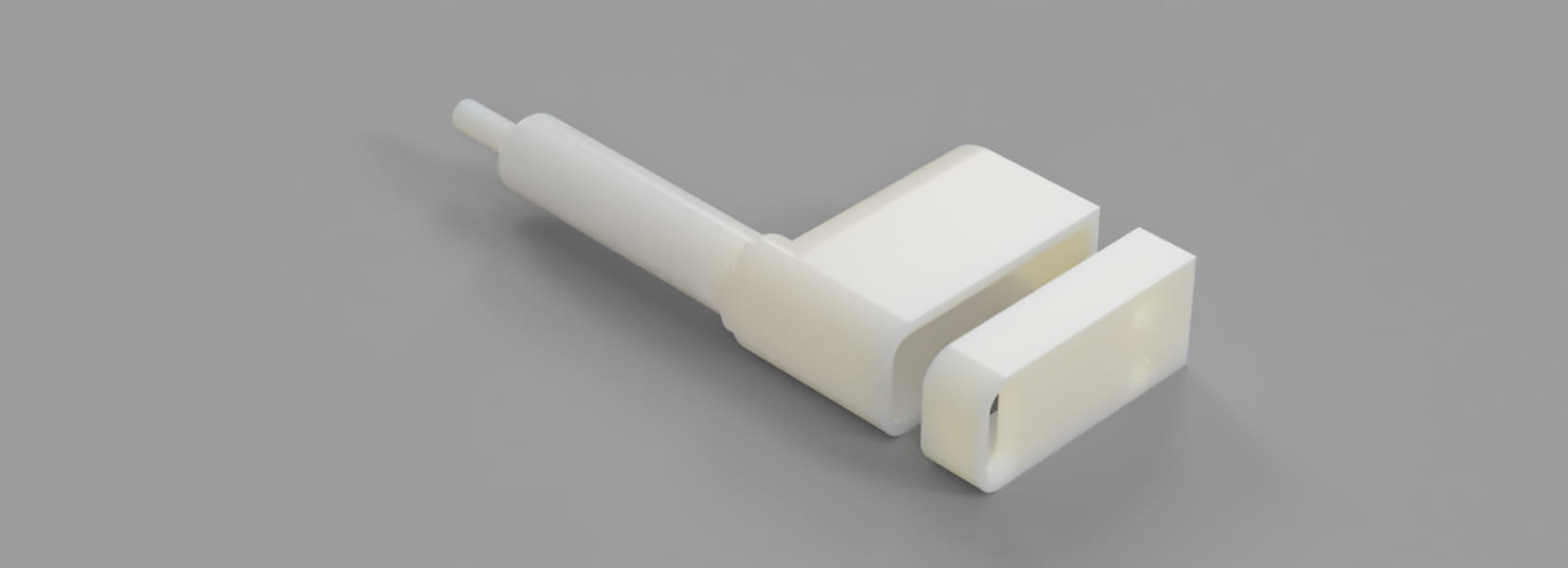

The project uses a handheld injector resembling a rotary tattoo device to deliver granulated PLA into a person’s dermis layer of skin. Upon entering the body, the process of hydrolysis begins where the polylactic acid microplastic particles will be slowly turned into lactic acid, carbon dioxide, and water. After thirty weeks the body will have completely recycled the PLA particles and excreted its constituent components through urination or respiration.

The handheld injector is based on the old-style rotary tattoo machine but is made using 3D printed parts, electronics, a small motor, a tattoo needle, etc. It is adapted from an open-source do-it-yourself tattoo project from GitHub.

The handheld injector tattoo machine will create semi-permanent tattoos and should last approximately 6 months before your body absorbs and excretes the PLA.

The project aims to add potentially seven billion humans as recycling units to the world’s current recycling infrastructure. It is a radical thought, one that needs time and further research to see its adaptability and usability in the real world scenario.

PROJECT DETAILS

Biorecycling Machine Base: (160 x 100 x 60 mm)

Hand-held Injection device: (165 x 70 x 30 mm)

PLA 3D printed components: Acrylic, electronic components, tattoo needle, PLA/saline solution, latex-free gloves, and fasteners

ABOUT MATT HARKNESS

Matt’s design interest centres around 3D printers and other small-scale digital fabrication technologies and how they can be effectively used in makerspaces and domestic settings. From the perspective of critical and speculative design, he prefers hands-on methods and conducts material explorations using a broad range of media, including wood, concrete, plastic, and re-purposed objects.

SUBSCRIBE TO OUR NEWSLETTER

IMAGE GALLERY

SHARE ARTICLE

COMMENTS